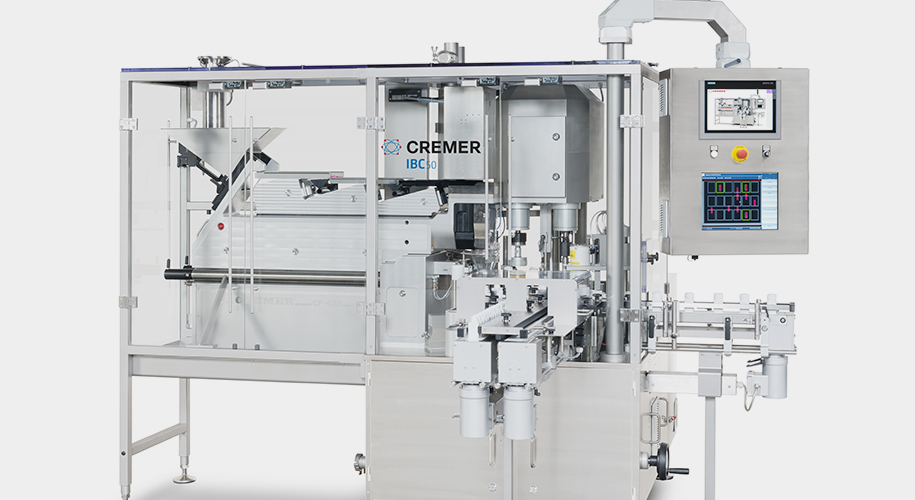

The perfect choice for cost-effective entry into bottle packaging automation. Whether round, oval, rectangular, or special-shaped bottles: the IBC 50 processes a variety of bottle shapes equally efficiently and... Read more >

The perfect choice for cost-effective entry into bottle packaging automation. Whether round, oval, rectangular, or special-shaped bottles: the IBC 50 processes a variety of bottle shapes equally efficiently and reliably, and it features Cremer‘s renowned 100 percent tablet and capsule counting accuracy.

- Small footprint

- Integration of functions according to customer requirements: from the counting system to the labeler in one machine

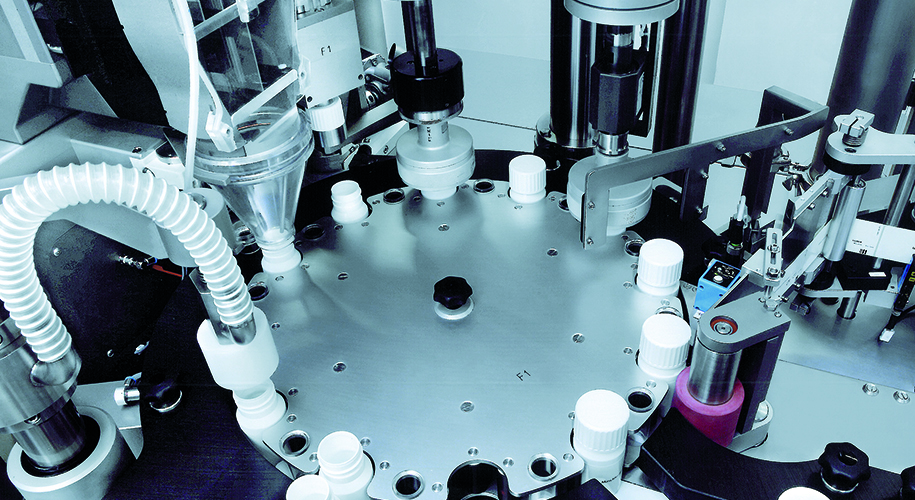

- Intermittently driven star wheel of GMP-compliant design

- Good accessibility and visibility throughout the entire process

- All parts in contact with the products are made out of FDA-compliant materials

- Optional containment features – for reliable operator and product protection

Technical data

| Max. bottle diameter | 80 mm |

|---|---|

| Max. bottle height | 160 mm |

| Max. output | 50 bottles / minute |